History

Americad Technology began in 1977 as a traditional model shop combining the talents of two professional model makers, one from a design oriented background, and the other from a technical background. Mark Haslett's experience has been in architectural and new product development. Michael Wright's has been in dynamic test models and military hardware.

Americad evolved proprietary techniques that has allowed product developers to take the prototyping process directly to production without additional tooling.

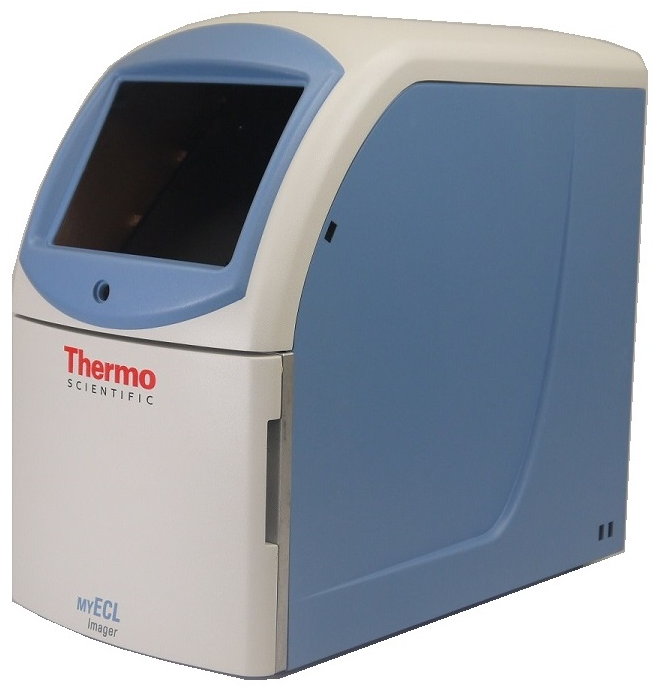

From Americad’s early work in engineering models of military hardware and mini-computer enclosures, we have evolved into a production-oriented manufacturer of plastic enclosures, principally bio-medical instruments as well as robotics, optical test and other monitoring, and electronic control systems.

But the most important step in our process is still the prototype run. Everything we do begins with a model, whether we’re doing 20 parts or 2000.

Though intimate with the variety of rapid prototyping technologies from their earliest days, we have transitioned away from purchasing SLAs to in-house Fused Deposition Models (FDM) because of their greater strength and long-term stability.

By building its own Fused Deposition Models, (or 3D Printing) Americad is at the forefront of manufacturing technology.

Now Americad combines that cutting edge process with its traditional modeling skills to produce sturdy, stable, and aesthetically pleasing prototypes and cast urethane production parts.

Our materials experts can help you choose from a broad range of polyurethane thermoset plastics or silicones to address your specific needs for flexibility, strength, durability, and service temperature. Rubbery handles over metal armatures is a growing product line.

Please look over our gallery to see the variety in our work.